General Treatment solvent-assisted low temperature separation technology

Application scenarios and objects

· Enterprises producing waste (sludge) of various types: such as hazardous waste treatment center (need to increase pre-treatment), oil refinery

· High oil content, high viscosity, high condensate and other difficult to deal with sludge: such as tank cleaning sludge, waste oil-based mud, rock debris, tank cleaning sludge, cold rolling sludge of steel mills, etc

· High value-added organic matter purification and separation: coal liquefaction residue purification asphalt, waxy oil purification

Technical advantage

· Strong universality: suitable for all kinds of oil-bearing, viscous sludge reduction, resource and harmless disposal

· The reduction is obvious: the solid water content after treatment is generally <30%, the oil content is generally < 2%, and the reduction rate is generally > 80%

· Good economy: the water phase in the sludge can be separated without evaporation, the oil recovery rate is > 90%, and the recovered oil is of high value

· Mild operating conditions: no strong acid and base, atmospheric pressure, temperature <100 ℃, solvent in a closed system cycle

Technology Introduction

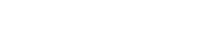

Solvent assisted low temperature separation technology is also known as "non-evaporative sludge treatment technology", the technology at room temperature and pressure, the application of efficient solvent formula (hydrocarbons, no metals, organic chlorine, sulfur, benzene ring), supplemented by a specific combination of processes and equipment, the difficult separation of water, solid, oil mixture into water, solid, oil three phases, and the solvent can be recycled. The process flow is shown in the figure.

Solvent assisted low temperature separation technology flow diagram

The process mainly includes 6 operating units, which mainly include:

a) Mixing/dispersing units

At normal temperature and pressure, the circulating solvent is fully mixed with the sludge, the stable emulsification system in the sludge is broken, and the oil droplets adhering to the surface of the solid particles are removed. After solvent treatment of the sludge, the solid becomes very easy to settle, and the liquid-solid mixture enters the liquid-solid separation unit.

b) liquid-solid separation unit

The liquid-solid mixture discharged from the mixing/dispersion unit enters the liquid-solid separation unit, such as a centrifuge with continuous feed and continuous discharge, which is separated into the liquid phase and the solid phase, respectively, into the liquid-liquid separation unit and the solid treatment unit.

c) liquid-liquid separation unit

The mother liquor discharged from the liquid-solid separation unit is separated into aqueous phase and organic phase under specific technological conditions. Through the density difference, the aqueous phase and the organic phase are separated in the liquid-liquid separation unit and enter the aqueous phase treatment unit and the solvent purification unit respectively.

d) Water phase treatment unit

The water phase after liquid-liquid separation is removed by stripping the trace solvent, and the treated water phase generally contains less than 100ppm of oil and less than 2000ppm of COD, and enters the sewage treatment plant for subsequent treatment.

e) solvent purification unit

After liquid-liquid separation, the organic phase contains solvents and oil products. Through the solvent purification unit, the solvent in the organic phase is separated from the oil products, and the solvent is recycled to the mixing/reaction unit for reuse.

f) Solid treatment unit

The solid after liquid-solid separation contains trace solvent, which needs to be further removed, and the solvent after removal is reused. The water content of the treated solids is generally less than 30% or lower, and the oil content is generally less than 2%.

Technical advancement search

143 Chinese and foreign literatures (including patents) published at home and abroad were searched, and 13 relevant literatures were selected. There are no other reports that are the same as the main points of this process.

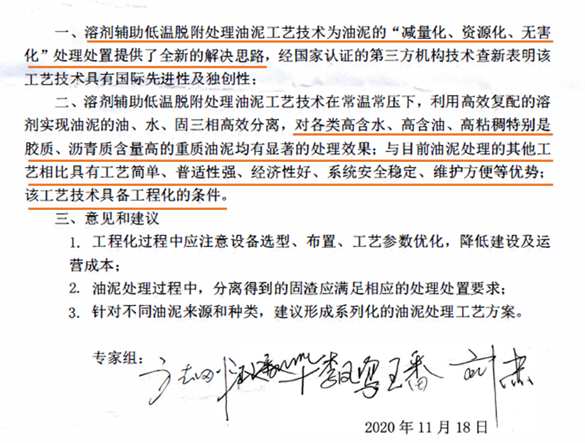

Process technology expert demonstration

Expert review site Review conclusions and recommendations

In 2020, the industry experts reviewed the solvent-assisted low temperature separation technology of Zhongke Guotong. Members of the expert group are from Liaoning Provincial Environmental Protection Department, Liaoning Provincial Environmental Protection Group, Tianjin Ecological Environment Comprehensive Protection Center, petrochina Liaohe Oilfield Branch, Sinopec Jingmen Petrochemical Branch and CNOOC Environmental Protection Service (Tianjin) Co., LTD. After technical review, the expert group said that the technology is a new oily sludge treatment solution, with international advanced and original; And strong universality, good economy, simple process, stable and safe, with engineering conditions.