Integrated solutions for the yard and station

Application scenarios and objects

(1) Hazardous sludge waste disposal center: The types of sludge collected and stored are many and the components are complex

(2) Centralized disposal point of oilfield sludge: large stock, many types of sludge, many impurities, and bad properties of sludge

Customer/industry pain points

Poor universality: the same sludge treatment process can not effectively deal with different sources of sludge, the composition of large differences, especially can not effectively deal with all kinds of high oil content, high viscosity gum, asphaltene sludge;

Poor reduction: the prior art can not effectively remove the oil and water in the solid slag, resulting in high oil and water content of the solid slag after separation, which needs to be further dried;

Poor economy: sludge treatment energy consumption is high, the removal of water in sludge basically depends on evaporation; The recycling rate of oil is low and the quality is poor. Sludge treatment brings great water treatment load;

Poor stability: Due to the poor deoiling and dehydration effect of the existing process, it is easy to cause the coking of subsequent hot drying, thermal analysis and other equipment, and the stability and processing capacity of the equipment are reduced.

Sludge treatment program of General Treatment

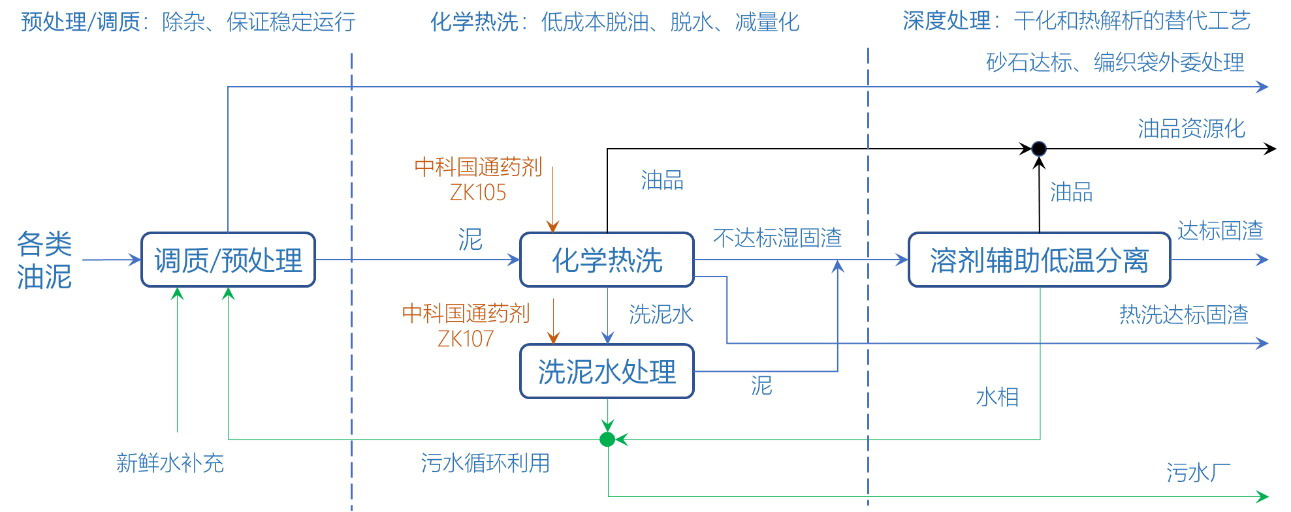

Over the years, based on the basic research of more than 200 kinds of sludge physical properties, the investigation of customers' pain points in different fields, the full comparison and selection of existing sludge treatment technologies, combined with the experience of a number of solid waste treatment projects, the company has proposed a general comprehensive solution for sludge treatment. The scheme is based on the premise of meeting the standard treatment and aiming at the optimization of comprehensive operation cost. The technical route of the scheme is shown below.

油泥处理综合解决方案技术路线图

Process section description

Conditioning/pretreatment: multi-stage sorting to remove impurities to ensure stable operation of subsequent processing;

Chemical hot washing: low-cost deoiling, dehydration and reduction processes;

Solvent-assisted low temperature separation: It effectively realizes three-phase separation of sludge under normal pressure and low temperature (< 100℃), which is an alternative process for drying and thermal analysis;

Sludge washing water treatment: oily sewage deoiling, deoiling water can be reused to wash mud;

Depending on the material condition, the processes can be used in series or parallel.

Technical characteristics and advantages

Good universality: It basically covers all kinds of oil-bearing, water-bearing and viscous sludge produced by various production links of oil fields and refining and chemical enterprises, and the process design fully considers the changes in the composition and properties of all kinds of sludge, which can reduce the oil content of solids to below 2% or even below 0.3%.

Operation flexibility: combined sludge treatment comprehensive program, the three technologies can not only parallel processing of all kinds of sludge (such as the amount of sludge inventory, need emergency treatment), but also series processing (deep treatment), operation flexibility. Even when accepting fluctuations in the amount of material, it can ensure that the overall operation is more economical.

Low comprehensive operating cost: The scheme takes the lowest comprehensive operating cost as the core. According to the type of sludge, the most economical treatment technology is matched. For the large and complex sludge, the combined process is adopted: First, the highly efficient chemical hot washing process of Zhongke Guotong is adopted to achieve the sludge reduction in the most economical way, and then the solve-assisted low temperature separation process of Zhongke Guotong is adopted to further treat the reduced sludge and reduce the oil content in the sludge to less than 2% or even 0.3%.

High resource utilization rate: All the technologies in this program have the process of recovering crude oil, and the comprehensive recovery rate of crude oil is more than 90%, especially the non-evaporative sludge treatment technology of Zhongke Guotong patent technology, which is especially suitable for the treatment of oil sludge with high oil content, the crude oil recovery rate is generally more than 95%, and the quality of recovered oil is higher, the general water content of recovered oil is less than 3%, and the ash content is less than 1%.

Highly integrated: All the technologies of this solution are modular installation, high integration, flexible equipment, small footprint, can be added or reduced according to the processing needs.

Project case description

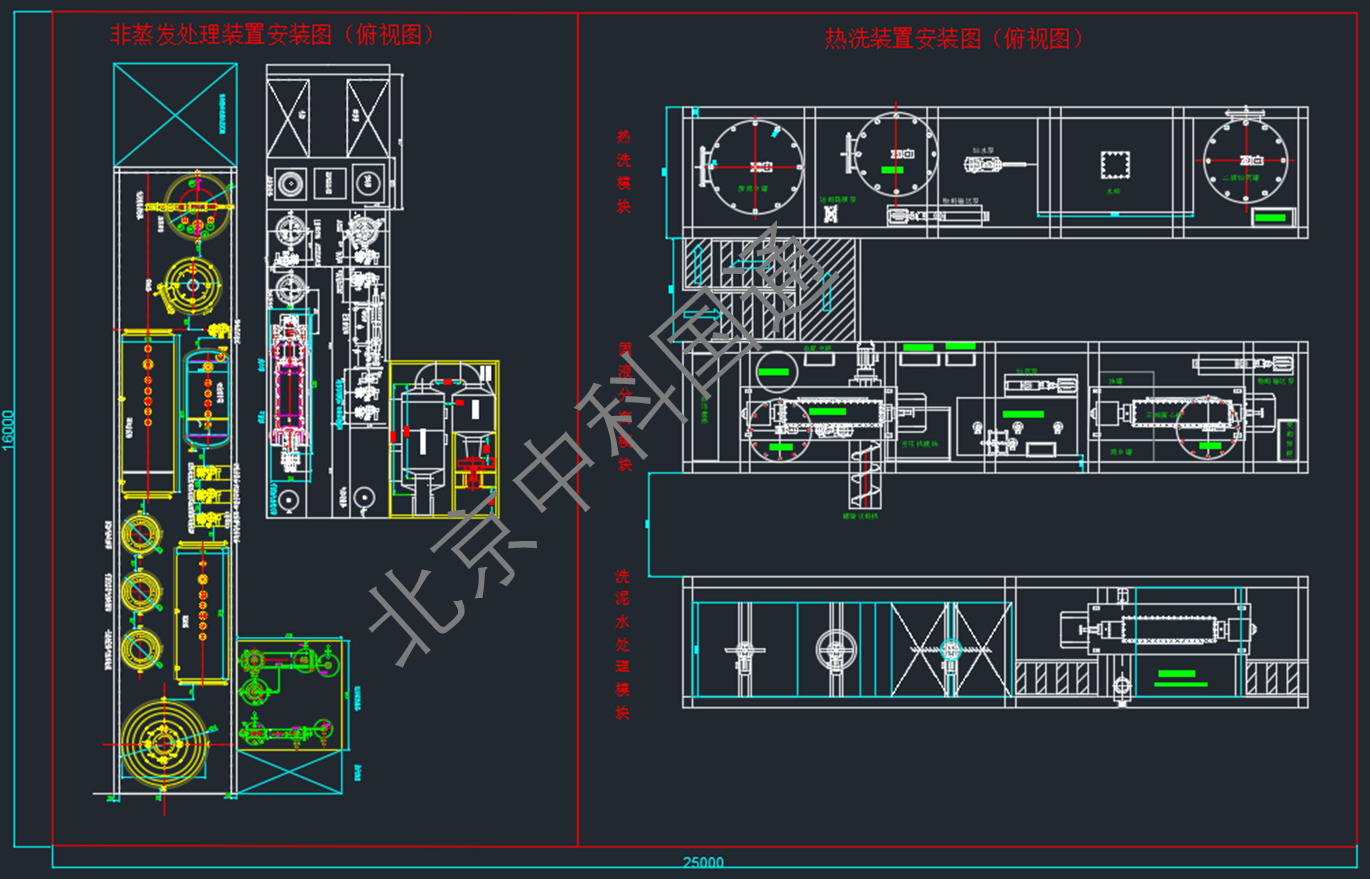

20,000 tons/year sludge treatment device installation diagram (overlooking)

Device description: An oil field 20,000 tons/year scum sludge, tank sludge reduction, resource and harmless skid installation device;

Main equipment area: 400 square meters (about 15 meters ×25 meters);

Equipment range: 20,000 tons/year chemical hot washing device + solvent-assisted low temperature separation device + 50,000 tons/year mud washing water treatment device;

Treatment index: After treatment, the solid dry base oil content is <2%, the oil recovery rate is > 90%, the sewage circulation washing mud, the discharge meets the sewage plant entering the plant index;

Current status: Installation and debugging phase